High Pressure Grinding Roller Has Become Popular Solution For Mining Companies Owing To Reduced Power Consumption And Steel Wear

|

| High Pressure Grinding Roller |

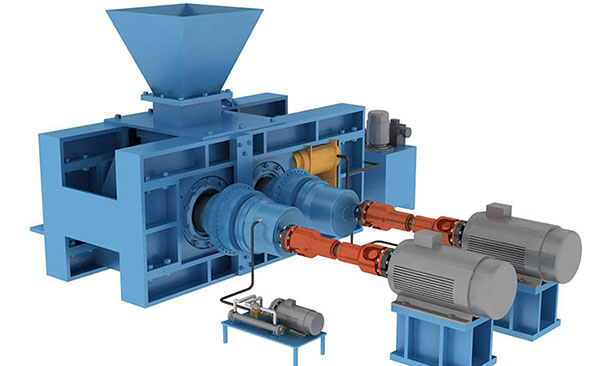

High

pressure grinding roller is a crushing technology that uses static pressure to

reduce the size of materials. It is a type of grinding technology that can be

applied in the mining sector. It is an energy efficient and cost effective

alternative to conventional crushing equipment. It can also lower energy

consumption by up to 40% and reduce maintenance costs. It is suitable for a

wide range of applications in both the metals and minerals sectors, including

comminution circuits, gypsum processing, base metal liberation and pellet feed

preparation.

The

emergence of new mining operations and expansion of existing ones will increase

the demand for High Pressure Grinding Roller

in the coming years. In an High Pressure

Grinding Roller application, the circumferential speed of both rolls needs to

be closely matched to minimize wear, ABB points out. Furthermore, it is

important to equalize the torque between the two rolls. This is achieved using

an integrated drive system with master-follower control modes that can

automatically adjust the load sharing. This will prevent one roll from

overloading permanently and minimize roller wear.

The

demand for High Pressure Grinding Rollers in mineral processing industries is

increasing due to their high energy efficiency and low operational and capital

costs. They can also be used in place of conventional grinding machinery to

save energy and achieve the same result. Moreover, they offer several benefits

such as reduced noise pollution and dust generation, easy operation and

maintenance and long service life. This has prompted companies to replace

conventional grinding equipment with High Pressure Grinding Rollers. The

growing concern about environmental issues is prompting mining companies to

adopt energy-efficient solutions to cut down on their operating costs.

In

the comminution industry, High Pressure Grinding Roller is considered to be one

of the most efficient grinding systems. It reduces the particle size of feed by

a force of compression between two counter rotating rollers with a small gap,

and it utilizes the rock’s densities to achieve the highest energy efficiency

in comparison with any other available technology.

With

a low operating cost due to reduced power consumption and steel wear, High

Pressure Grinding Roller has become an increasingly attractive solution for

mining companies facing rising operational costs from mining taxes and energy

costs. Furthermore, the technology is easy to operate and has a compact

footprint that makes it ideal for plant modifications or upgrades.

In

April 2022, Thyssenkrupp Polysius was assigned the supply of two complete roll

unit. This order is being carried out in cooperation between the American and

German Service Teams and the delivery is scheduled for March 2023.

Comments

Post a Comment