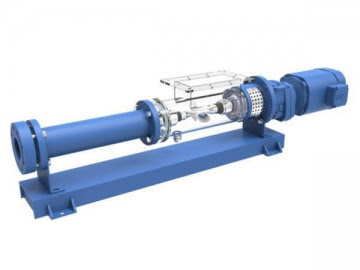

Progressing Cavity Pump; Is Pumps Liquids That Have High Density

|

| Progressing Cavity Pump |

A

Progressing Cavity Pump is an

effective dislodgment pump using a helical worm rotor and stator assemblage to

make short term cavities to extract liquid into, which development from the

pump causing in the liquid being excluded from the release port. A

distinctive progressing cavity pump shows a suction cove which inserts into an

increasing casing. In this casing fixes a helical worm rotor and stator meeting.

The rotor helix is fixed off-set to the stator making cavity features in the

assembly that are formed by acute seals as the rotor associates the base of the

stator. As the rotor starts to rotate in an unconventional fashion, the

cavities create, extract in goods and are developed through the assembly and

the goods are discharged from the release port.

A

Progressing

Cavity Pump shines while tackling highly thick liquids that are

needed to be shifted enduring distances. General liquids may comprise slurry,

purees, tissues, dough from left-over water treatment plants, anaerobic

assimilation services and paper reprocessing plants. As the flow rate of pump

is relative to the pump speed and can be utilized for the dosage of thick

liquid such as flavors and chemicals. Designs are accessible for dosage-type

uses, healthy surroundings and drum-discharging. Progressing cavity pumps can

be modified and particular with a range of addition compounds and formations to

billet the harsh liquids it is projected to tackle.

Instances

comprise the inlet feed with various screw and splash feeders to fragment up

solids, mechanical seal deals to secure over highly abrasive wear,

healthy-compliant substances and formation, compact build dosage type pumps,

vertical build components for barrel evacuating, Progressing Cavity Pump must not work on dry as the heat produced

by the blade and stator can lead to outbreak - Anyhow there are several

accessory inclusions to cure over this, from the suction area and on the

pump. Progressing cavity pumps are accessible with several geometries,

usually in various ratios, which impact the amount of entrance of the goods

into the next cavity and the amount of efficacy and covering between every

cavity.

Regular

geometry is generally best for dense substance as the pitch enables for the

thickness of the goods while long geometry with shallow bends and vast surface

contact amongst the rotor and stator offers more efficacy. Progressing Cavity Pump are excessive for gentle dosage of hard

media such as solids and cuts – even at huge pressures and thickness.

Self-priming and valve-less, they have ideal capacities. They can tackle low

and vastly thick material, and solids such as fruit and vegetables.

Comments

Post a Comment