Microfluidics; a Form of Laboratory Technology That Enables Researchers to Work with a Reduced Sample Size at Lower Cost

|

| Microfluidics |

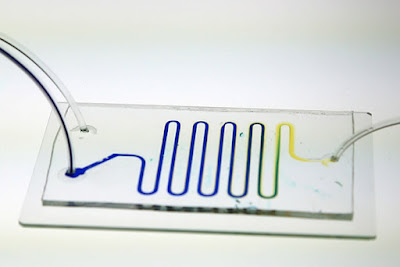

Microfluidics

involves the manipulation of fluids at the microscale. It is a form of

laboratory technology that enables scientists to work with a reduced sample

size and at lower cost. As a result, scientists can conduct experiments with a

higher degree of confidence and a reduced limit of detection. For example, when

conducting a study, a scientist can perform a high throughput cell culture with

a microfluidic lab-on-a-chip. This form of technology can be used to study

single cell behavior, intercellular communication, and cell locomotion. These

results are comparable to macroscopic culture assays.

When

working with a Microfluidics

lab-on-a-chip, a scientist must consider several factors in order to make

effective use of the system. One of the main considerations is the type of

material used for the chip. Many devices are made of polymer, such as PDMS

(polydimethylsiloxane). The material can be transparent and easy to bond to

glass. Moreover, it is highly permeable to gases. Another consideration is the

relative pressure in the chip. If the chips are made of PDMS, a relative

pressure of about two Bars should be maintained. However, if the chips are made

of thermoplastic, the relative pressure may be increased by as much as 10 Bars.

For

the same reason, it is important to design the Microfluidics channels with a constant depth. Changing the depth

should be done in a step-wise manner. A change in depth can affect the gas

exchange and the turbulence of the fluid.

Microfluidics

devices also allow for rapid drug changes. The device can be used for sorting,

mixing, and pumping. Also, it can be used to monitor a variety of biochemical

environments. They have a dual channel configuration, which reduces the

variation in experimental results. Microfluidic devices can be made of several

materials, including PDMS, glass, and silicon. Each of these materials is able

to be shaped, which means it can be fabricated into various shapes. Some of

these microfluidic components are molded, while others are manufactured with a

DRIE process. In November 2022, LumiraDx announced the launch of Rapid

Microfluidic Immunoassay C-Reactive Protein Test for helping combat

Antimicrobial Resistance in India.

Comments

Post a Comment