Engine Actuators; Are Used To Control Air Flaps For The Torque And Minimization Of Power And Fuel Management For Combustion

|

| Engine Actuators |

An Engine Actuator is a

device that is accountable for the movement and regulating a system such as

opening the valve or a powerhouse. An Engine

Actuator needs a regulating device which is controlled by the control

signals and an energy source. The control signals are comparatively less energy

comprising and might be electric power or current, or the hydraulic fluid

pressure or in human power. Its key energy source is an electric current or the

pneumatic pressure.

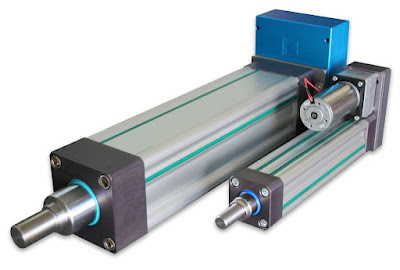

Control device is an exclusive valve and at the time it gains a control signal, the actuator retorts by transferring the energy sources into the machine-driven motion. Engine Actuators is a form of mechanism through which the control system mimics upon to conduct a work or task. The control system used in the engine actuators use simple or software based or the human input or any other form of input. There are several types of engine actuators. Soft actuators are those which can change the shape with respect to stimuli comprising thermal, electrical and mechanical.

Hydraulic actuator comprises of container or liquid motor that employs hydraulic power to provide mechanical functions or workings. The mechanical motion gives them an outcome as of linear, rotatory or the oscillatory motion. As liquids are not possible to be compressed, a hydraulic actuator can provide a huge force. The accessibility of limited or restricted acceleration is the only disadvantage of the hydraulic actuator. The hydraulic cylinder consists a hollow cylinder-shaped pipe due to which a piston can move.

The word unit acting is used to provide the piston an opposite stroke and the word dual acting is employed to indicate the pressure used on every side of the piston. Pneumatic Engine Actuators gives a considerable force or pressure to be created from a small pressure alteration. Pneumatic vitality is considerable for regulating the main engines as it can rapidly react initially and ending as the control sources is not required to store in return for working. The growth and demand in the fuel-efficient vehicles is leading to the rise in engine actuators. As per IEA, there were around 16 million fuel-efficient vehicles in United States.

Comments

Post a Comment