Polyphthalamide is an excellent thermoplastic resin with a good blend of strength and thermal properties

|

| Polyphthalamide |

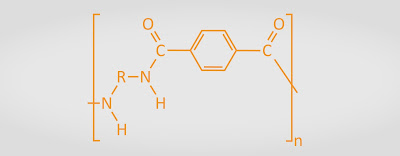

Polyphthalamide is a subset of the

polyamide family, a group of thermoplastic synthetic resins. This class of

resins contains both terephthalic and isophthalic acid as its primary

ingredients. It is used to create various kinds of materials such as films,

coatings, and textiles. In terms of use, it is widely used in the automotive

industry. Its mechanical strength, good heat stability and dimensional

stability make it ideal for this purpose. This material can also be easily

molded, making it very convenient for manufacturers. Because of its superior

performance, it is used over conventional metals in many industries. It is an

excellent thermoplastic resin with a good blend of strength and thermal

properties. These qualities make it particularly attractive for various applications.

Its resins with at least 50% aliphatic terephthalamide units exhibit excellent

thermal properties. They have high melting points, as well as high melt

viscosity and low degradation temperatures.

The aliphatic diamine component of Polyphthalamide

comprises aliphatic, cyclic, or aliphatic ring-type radicals with four to

fourteen carbon atoms. These aliphatic diamines can be substituted or

unsubstituted and are compatible with polyphthalamide.

It is a high-performance resin and a

member of the nylon family. It has excellent thermal and mechanical properties

and is suitable for injection molding. Many PPA grades contain fillers such as

glass or mineral to provide more stiffness in high-temperature applications.

This type of polymer is popular for cutting utensils and other appliance parts.

Polyphthalamide is a semi-crystalline

polyamide with enhanced chemical resistance. Its dimensional stability, low

water uptake, and excellent electrical insulation properties make it an ideal

solution for parts that are exposed to high temperatures and harsh chemicals.

However, commercial recycling requires a lower cost of virgin polymer and

logistics. There are many methods to recycle PPA, including incineration. Its

formulations with alkali metal salts are particularly useful for manufacturing

yarns and filaments. They also exhibit improved thermal stability. These

properties are especially useful for applications that require extended

exposure to elevated temperatures in the air.

Comments

Post a Comment