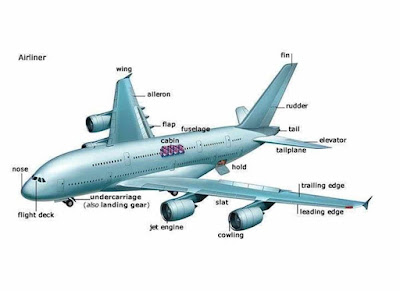

Aircraft Parts Include Landing Gear, Tail Assembly, Propeller, Engine, Cockpit Equipment, Wings, and Fuselage

|

| Aircraft Parts |

Many Aircraft Parts require high-quality materials

that can withstand the stresses of flight. While metal is the most common

choice for Aircraft Parts, other materials, such as plastic, can also be used.

These materials are durable and corrosion-resistant and can withstand the

harshest of environments. High-end plastics can be tough and reliable while

being lighter than metal. This can boost the aircraft's speed and fuel

efficiency.

Purchasing Aircraft Parts from a reputable supplier is

essential. An accredited aerospace parts distributor is required to have the

necessary paperwork to keep its parts approved. Accredited Aircraft Parts

suppliers have a strict supplier oversight program and internal receiving

criteria. Aircraft

Parts have

well-trained personnel, which can provide buyers with the necessary

information. The tail of an aircraft is a complex structure made up of several

parts. The tail has a vertical stabilizer (also known as a fin) and a rudder,

which control the direction of flight. The rudder is operated by pedals or

foot-activated switches. In regions such as the United States, the prevalence

of aircraft companies has increased the usage of Aircraft Parts.

The FAA requires aftermarket parts manufacturers to

obtain a PMA, which allows them to sell Aircraft Parts to other aircraft

manufacturers. To apply, a manufacturer must indicate which products their

parts will be installed on. They must also give the name and address of the

facility building their parts. In addition, manufacturers must provide

documentation, such as drawings or specifications of the parts. These drawings

or specifications should include the material, configuration, and measurements

of the part. The documents should also include any tests or calculations that

the part has passed.

The aerospace industry has been utilizing 3D printing

to manufacture Aircraft Parts. These parts offer several benefits, including

lightweight, detailed component unitization, and bill of materials

consolidation. It also allows companies to scale their manufacturing capacity

effectively. The manufacturing process used for Aircraft Parts allows them to

be produced more efficiently than ever.

Comments

Post a Comment