Melamine Formaldehyde Demand Is Growing In Furniture, Automotive, And Construction Industries Due To Its Various Beneficial Properties

|

| Melamine Formaldehyde |

Melamine

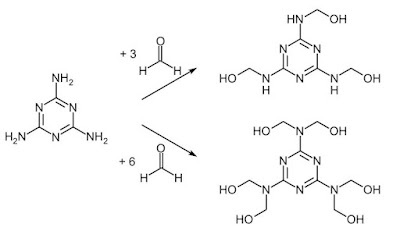

Formaldehyde resin is a polymer that is formed by condensation between

formaldehyde and melamine. The resulting hexa-hydroxymethyl derivative

undergoes further condensation and crosslinking, producing melamine resin.

Several bifunctional analogues of melamine control the resin's properties,

allowing the material to be used for a variety of applications. Some common

uses of melamine foam include insulation, soundproofing, and cleaning abrasive.

Melamine

is also incorporated into flame-retardant materials, like foams and insulators.

Its flame-retardant properties are derived from the high content of nitrogen of

the compound. When melamine is exposed to heat, it degrades and releases

nitrogen, replacing oxygen in surface air and preventing the material from

burning. Paints and varnishes contain butylated melamine resin. Moreover, a

copolymer of sodium bisulfite, melamine, and formaldehyde creates foams with

sound-absorbing properties.

The

reaction time of Melamine

Formaldehyde resins depends on the ratio of melamine to ethylene

glycol. The molar ratio of the two compounds varies from 0 (MF1) to 2 (MF5). In

general, the higher the molar ratio, the shorter the gel time and worsening

storage stability. In our research, the MF resins with ethylene glycol and

caprolactam contained lower amounts of free formaldehyde than MUF resins. The

reaction between melamine and formaldehyde produces methylolamine. In the final

cured product, methylene bridges are present in the Melamine Formaldehyde resin.

The chemical reaction is complex and requires multiple steps to complete. Melamine

Formaldehyde (MF) is an excellent crosslinking agent. Its properties make it a

versatile chemical.

Along with

containing formaldehyde, melamine is also used as an adsorbent in a variety of

materials. This adsorbent can be grafted with polyethyleneimine, and it is also

sometimes used as a wood adhesive. Melamine-based resins are less effective for

many encapsulation applications, because they lack the chemical backbone and

three-dimensional network needed to be effective. Due to its excellent

compatibility with a wide range of resin media, HMMM resins have secured their

place in coating compositions. Available as a waxy solid or modified liquid,

HMMM is soluble in water, most common organic solvents, and compatible with

almost all resin media. In March 2022, Allnex, a leading supplier of resins for

sustainable coating solutions, acquired the Mahad Manufacturing site and

coating resins business of D.R. Coats Ink & Resins Pvt. Ltd. in India.

YouTube

Link- https://www.youtube.com/watch?v=PX_1fElDJVo

Comments

Post a Comment