Fluoropolymer Films Are High-Performance Polymer Films Composed Of Fluorine And Carbon Molecules

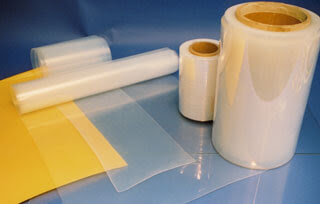

Fluoropolymer films are high-performance polymer films composed of fluorine and carbon molecules. These films are commonly employed in high-temperature applications as well as extremely hostile chemical environments. They are highly resistant to chemicals and moisture, have a nonstick surface, and are optically transparent. These films are widely employed in a variety of industries, including packaging, electronics, automotive, construction, electrical, and aerospace. Cable insulation, composite mould release, roll covers, pharmaceutical liners, anti-corrosive linings, adhesives, photovoltaic cell, microphone membranes, surface coverings, airbags, anti-graffiti coverings, and gasoline hoses are all applications for these films.

Fluoropolymer Films are cutting-edge materials that provide parts or manufacturing processes with superior chemical resistance, transparency, weather resistance, heat resistance, water absorption, and electrical properties, among other benefits. Fluoropolymer films are also employed as blister packaging materials in the pharmaceutical business. Fluoropolymer films are cutting-edge materials that provide parts or manufacturing processes with superior chemical resistance, transparency, weather resistance, heat resistance, water absorption, and electrical properties, among other benefits. They are the finest answer for an increasing variety of industries, including electronic, machine, automotive, and semiconductors.

High-performance fluoropolymer films are being evaluated for usage as components or in manufacturing processes due to their remarkable resilience to high temperatures and chemically harsh conditions. They fulfil the current demands of a growing number of diverse and sophisticated industries, including electrical, machine, automotive, and semiconductor. Chemical-resistant etching bath liners are required for semiconductor production equipment, reducing process downtime. Pharmaceutical packaging manufacturers are working to improve the barrier resistance of drug delivery systems, cap liners, and plunger laminates in order to create next-generation drug containers.

Fluoropolymer film has excellent properties such as chemical resistance, high temperature tolerance, low coefficient of friction, optical transparency, UV & weather resistance, fouling resistance, moisture resistance, high insulation, non-flammable properties, low surface energy, and low dielectric constant. Its distinct qualities make it ideal for a wide range of applications, including electrical and electronics, medical and pharmaceuticals, automotive and aerospace, and medical.

Comments

Post a Comment